The Blind Spot System (BSS) is a warehouse solution that alerts forklift operators of other forklifts or pedestrians approaching a blind spot, intersection, doorway or gate. The system can be used to trigger lights, buzzers, traffic lights or lock/unlock gates etc to indicate right-of-way between pedestrians and forklifts.

- Detection of trucks and/or pedestrians in the proximity of the traffic light.

- Easy installation.

- Durable and robust system components.

AREAS OF APPLICATION

- Loading and unloading zones

- Poor visibility areas at junctions between pedestrians and forklifts

- Areas with high forklift traffic

HOW THE SYSTEM WORKS:

The examples illustrated below are just a few of the many custom combinations the BSS can be configured to, including the addition of ShockWatch’s Pedestrian Alert System (PAS).

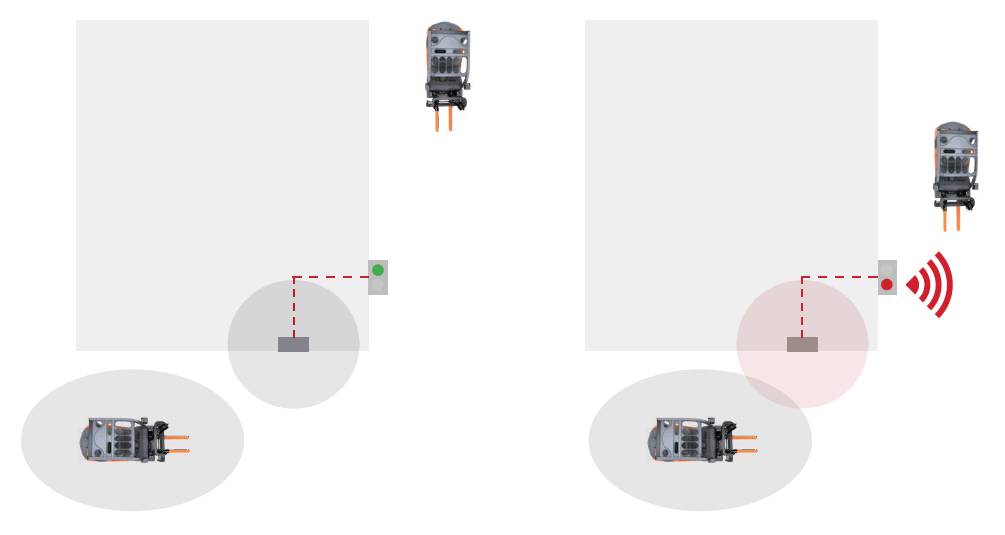

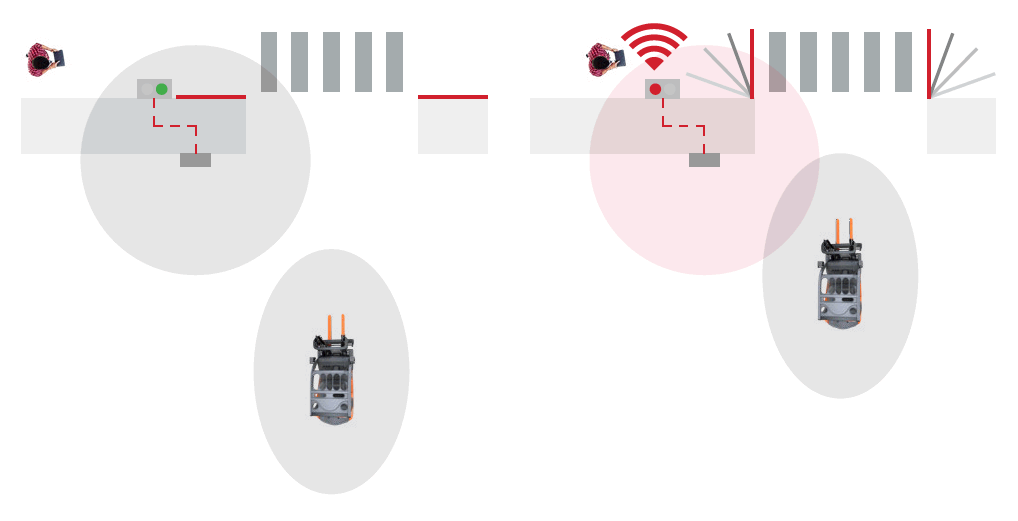

BSS Example 1

Forklift Detection – Blind Corner

System Components

- All forklifts are fitted with ShockWatch Pedestrian Alert System (PAS)

- A Tag is fitted to the wall

Main Operating Characteristics

- When forklift is detected in range of wall Tag, it triggers light and/or buzzer on blind side of intersection to alert oncoming traffic of approaching forklift or pedestrian

- Detection range up to 7m

BSS Example 2

Pedestrian Detection – Blind Corner

System Components

- All pedestrians wear ShockWatch Tags

- A Detection Unit is fitted to the wall

Main Operating Characteristics

- When pedestrian is detected in range of unit, it triggers a light and/or buzzer on blind side of intersection to alert oncoming traffic of approaching pedestrian

- Detection range up to 7m

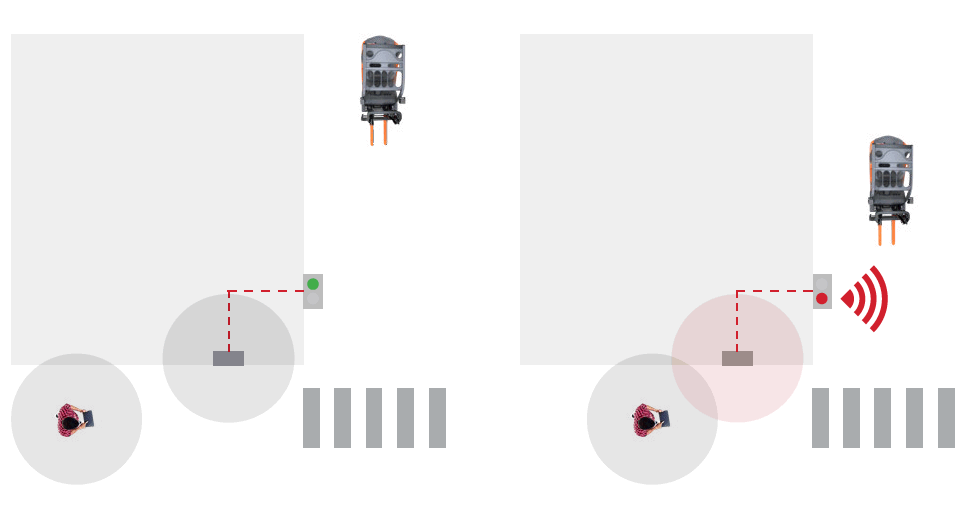

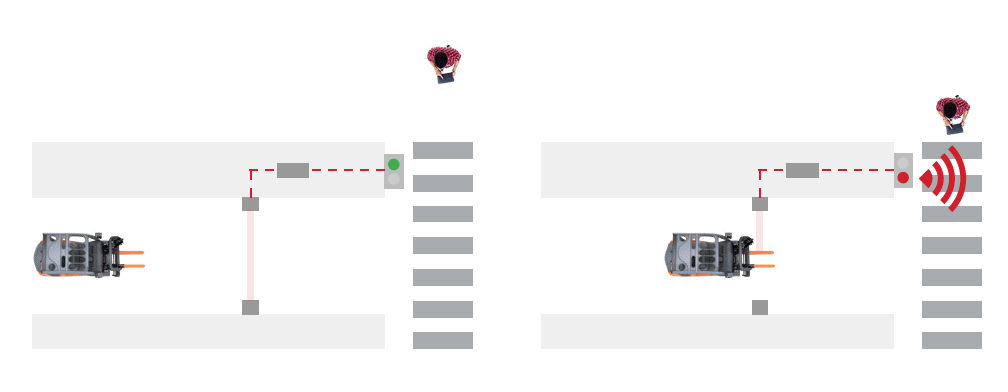

BSS Example 3

Forklift Detection – Doorway

System Components

- All forklifts are fitted with Detection Units

- A Tag is fitted to wall or ceiling

Main Operating Characteristics

- When forklift is detected in range of wall or ceiling Tag, it triggers light and/or buzzer on other side of wall to alert oncoming pedestrians of approaching forklift

- Detection range up to 7m

BSS Example 4

Forklift Detection – Gate

System Components

- All forklifts are fitted with Detection Units

- A Tag is fitted to wall or ceiling

Main Operating Characteristics

- When forklift is detected in range of wall or ceiling Tag, it triggers light and/or buzzer on other side of wall to alert oncoming pedestrians of approaching forklift

- Gates are locked on forklift approach. A manual gate override button can be installed in case pedestrian is caught in mid-crossing

- Detection range up to 7m

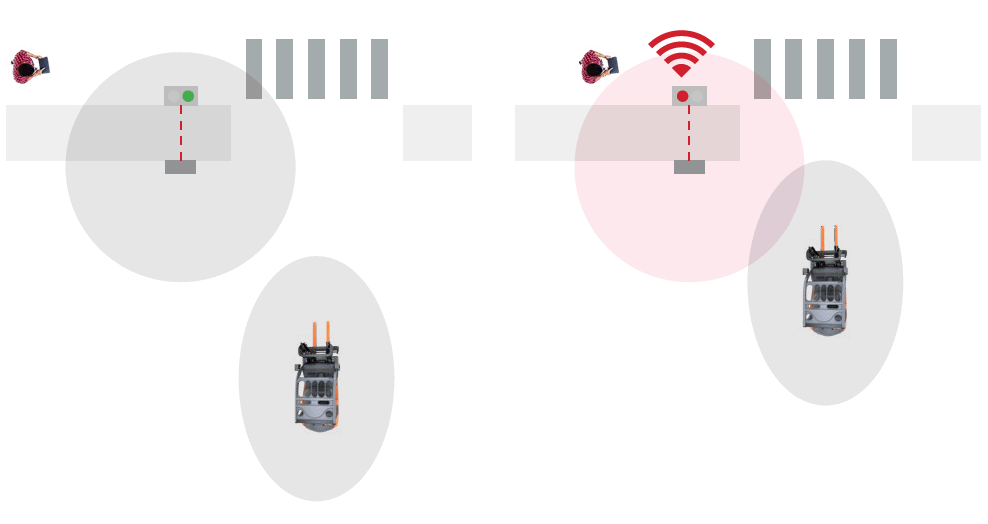

BSS Example 5

Forklift Detection – Beam

System Components:

- Reflector beam fitted near pedestrian crossing

- Reflector mirror fitted opposite reflector beam

- Control Unit connected to mains powe

Main Operating Characteristics:

- When forklift approaches pedestrian crossing a beam is broken to trigger the light/buzzer alert