OpsWatch WiFi Impact and Vibration Recorders allow you to improve the performance and safety of your equipment, extend its lifetime and avoid any unplanned downtime and maintenance.

Vibration and shock monitoring is an integral part of machine condition monitoring programs. Change in equipment vibration serves as an early warning of a decline in operating function and signals the need for maintenance to avoid more serious faults and/or failure. All equipment that has belts, gears, bearings, drive motors, and other moving components has a “normal” range of vibration during operating cycles

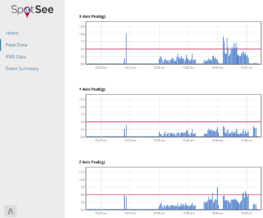

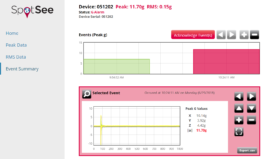

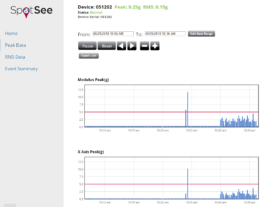

OpsWatch enables real-time monitoring of low-frequency shock and vibration to identify these changes when they happen. The system provides alerts when vibration is outside of the normal range and has the capability to stream condition-based data through WiFi communication.

See how our OpsWatch compares with it’s competitors here

Benefits

| Protect Equipment in transit and during operation with the only dual mode device in the industry. |

|

| Prevent Downtime by using the data and alerts provided by the OpsWatch system as part of your preventative maintenance program. Data and real-time alerts streamed through Wi-Fi communication into the easy-to-use condition monitoring software will help you to identify potential equipment faults before they occur. |

|

| Maximize Utilization by using OpsWatch in stationary mode, monitoring the day to day operation of your equipment. |

|

| Reduce Costs by using low frequency vibration and shock detection to drive preventative maintenance before expensive repairs or even equipment replacement is required. |

|

| Dual Mode Functionality both Transport and Condition Based Monitoring (CBM) functionality |

|

| Streaming Data communicate Precision Shock & Vibration Data through WiFi Connectivity |

Features

- Alert users to inspect equipment for potential damage

- Enhance preventative maintenance plans

- Real-time vibration monitoring allows fast corrective action

Applications

- Onshore Drilling (top drives)

- Offshore Drilling (top drives)

- Industrial Pumps

- Hydraulic Fracking

- Aggregate Material Equipment

- Conveyor Belt Driver Systems

- Pulp and Paper

- Fin Fans

- Industrial Combustion Gas Engines

- Iron & Steel

- Energy and Utilities

- Construction

- Pipe Vibration

- Waste Water Treatment Plants

- Cooling Towers

- Rotary Screw Compressors

- Facilities Management

- Mining