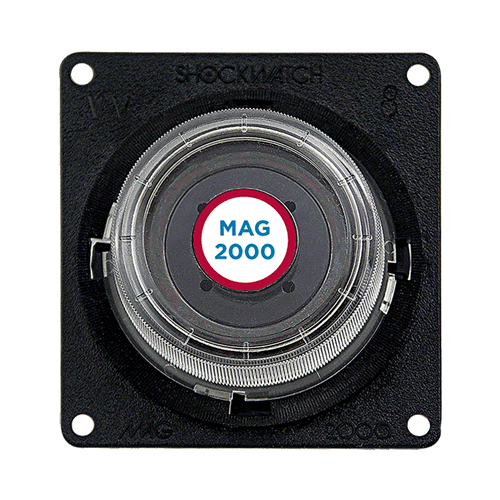

ShockWatch RFID combines the benefits of RFID inventory tracking with an indication of unacceptable handling. Each ShockWatch RFID unit has been fitted with a passive RFID chip which can be scanned with any standard RFID reader to catch damage before it enters the assembly line.

- Reduce damage by 40-60% by implementing a monitoring program that changes behaviour

- Easy to add to your current RFID program

- Used by the best supply chains around the world

- No wires or batteries

Based on the impact technology of the ShockWatch 2, ShockWatch RFID is a go/no-go device that will indicate if products have been mishandled during transit or in storage. The indicators are field armable, tamperproof and turn red when an impact beyond a specific threshold has occurred.

Features

- RFID Enabled Impact Indicator

- Field armable

- Tamper proof

- Serialised

- Acts as a visual deterrent to mishandling

- Expands the utility of RFID with damage monitoring

- Reduces receiving times and isolates items that need an inspection

- Reduces mishandling through awareness

- Helps identify trouble spots in the supply chain from production to transportation to storage

Applications

- Automotive Parts

- Medical Devices

- Healthcare

- Hospitals

- Electronics

- Packaging

- Logistics and Supply Chain

- Musical Instruments

- Furniture

- Medical Instruments

- Applicances

- Pallets

- Aerospace & Defense

- Glass

- Building Materials

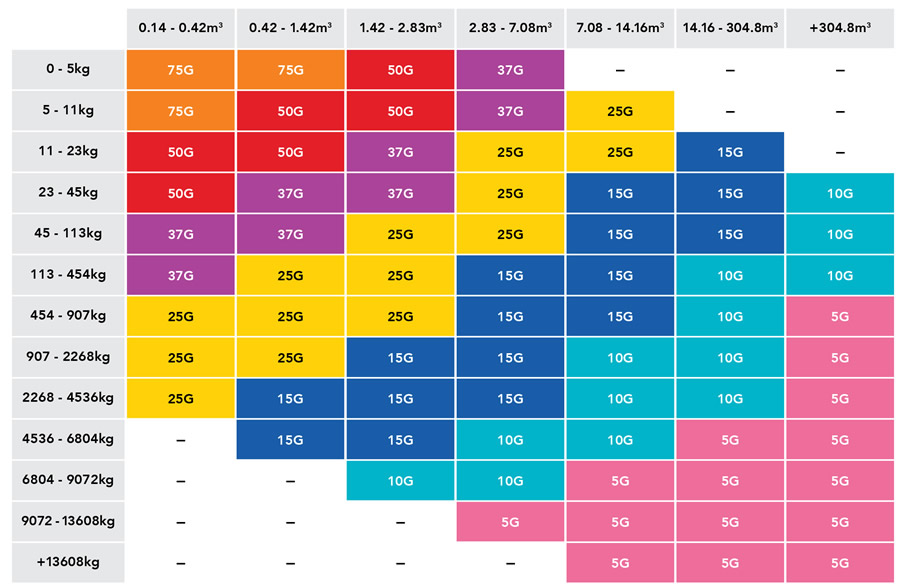

Shockwatch RFID Selection Guide

There are two things you need to know to begin selecting a ShockWatch RFID impact indicator sensitivity: shipment size (m³) and weight (kgs).

The selection guide should always be used as a starting point only. The ShockWatch 2 that will be best suited to your application will also take into account product fragility and packaging.

A Complete ShockWatch RFID Impact Indicator Program

The ShockWatch Program is more than just an impact indicator. A key element in the success of using ShockWatch RFID is companion tools. When used in conjunction with companion labels, alert tape and communication tools, ShockWatch RFID impact indicators become a highly effective damage reduction and prevention program.

Implementation of this program provides psychological reinforcement of proper handling procedures and changes the behaviour of material handlers. It provides a highly visible deterrent to mishandling throughout the supply chain and encourages package handlers to be more conscious of their behaviour and surroundings.

Success of the ShockWatch Program is measured by a reduction in damage. Preventing mishandling is the key to damage reduction.

Download our ShockWatch Impact Indicators Implementation Guide

Contact us for further information on the ShockWatch Program or if you would like any information on ShockWatch RFID Activation Curves.