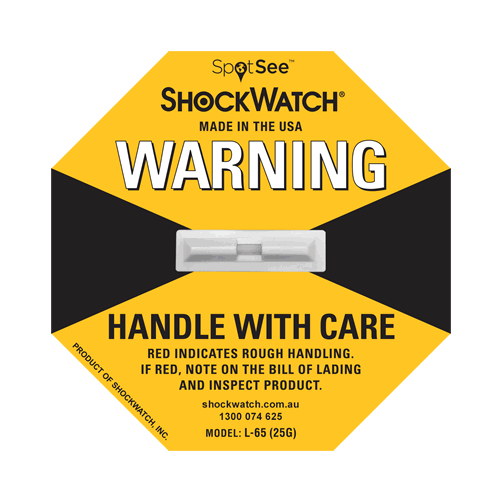

ShockWatch Clips impact indicators

Are highly visible impact indicator that alerts you if your product has been subjected to unacceptable handling. The single Clip has one tube and will provide nearly 360 degrees of detection. The double Clip has two tubes and gives a full 360 degrees of detection. Clips are mainly used either embedded or attached to the exterior of hand held and calibrated products.

ShockWatch Clips impact indicators are ideal when you need to know if product mishandling may have resulted in misalignment, loss of product calibration or warranty-related repair issues.

Lost Calibration for measurement equipment

Products such as measurement equipment, gyroscopes, weaponry or medical devices require precise calibration in order to operate properly. Impacts can result in misalignment of critical components.

ShockWatch Clips impact indicators indicate if an impact has been experienced that could potentially result in misalignment and the need for recalibration.

Warranty Abuse

Most companies offer a warranty period during which non-functioning products are repaired or replaced at no cost to the end user. Service calls involve labour costs of making repairs and overseeing administrative processes, spare parts costs and the costs associated with unhappy customers.

In order to monitor for mishandling, ShockWatch Clips can be integrated into or mounted on the product. These devices are excellent tools to improve customer handling and reduce warranty costs associated with mishandling.

Types of products that could be monitored with the ShockWatch Clips

- Hard drives

- Sensitive electronics

- Communications equipment

- Avionics / Gyroscopes

- Handheld electronic devices

- Audio visual / Broadcast equipment

- Medical equipment

- Laboratory equipment

- HDTV equipment

Applications

- Consumer Electronics

- Retail

- Aerospace and Defense

- Auto and Truck Parts

- Security Systems and Services

- Robotics

- Glass

- Electronics

- Sports Equipment

- Equipment Rental

- Appliances

- Water Treatment / Filtration

- Electronics – Computer Hardware

- Medical Devices and Supplies

- Industrial Equipment

- Construction – Supplies and Fixtures

- Chemicals/Petro-Chemicals

- Scientific and Technical Instruments

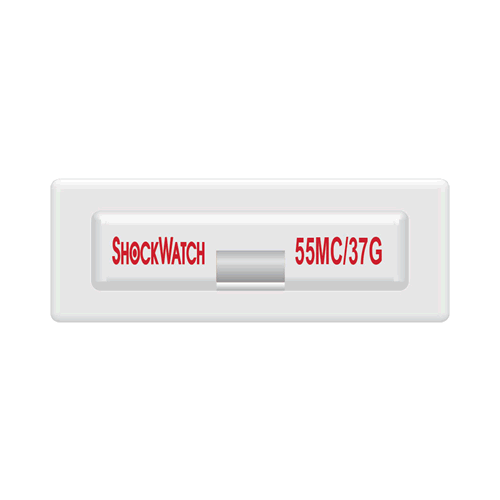

ShockWatch Clip Selection Guide

The selection guide should always be used as a starting point only. The final selection will be dependent on your specific product’s characteristics and your monitoring goals.

To select the proper activation levels, determine if shock specifications exist for the product to be monitored. Most complex electro mechanical products such as hard drives, avionics, analysis instruments, etc. have been through extensive testing to establish shock damage boundary data. If this information is available, the selection process is quite simple. Select the clip type and sensitivity to match.

All product is rated at 50 milliseconds

MC= clip with one window (single).

MCD = clip with two windows (double)

|

Product Name

|

Activation Height

(drops on hard surfaces) |

Application Examples

|

| 85MC, 85MCD (10G) | Activates at 5cm to 10cm |

|

| 75MC, 75MCD (15G) | Activates at 7cm to 15cm |

|

| 65MC, 65MCD (25G) | Activates at 10cm to 20cm |

|

| 55MC, 55MCD (37G) | Activates at 15cm to 35cm |

|

| 47MC, 47MCD (50G) | Activates at 20cm to 45cm |

|

| 35MC, 35MCD (75G) | Activation trends at 47cm to 61cm |

|

| 30MC, 30MCD (100G) | Activation trends at 61cm to 101cm |

|

| CX25 and CXX25 (150G) | Activation 76cm to 122cm |

|

| Flex 45/45 High G (150G @ 5msec) | Activation 76cm to 112cm | |

| Flex 40/55 High G (170G @ 5msec) | Activation 112cm to 148cm | |

| Flex 40/65 High G (195G @ 5msec) | Activation 148cm to 183cm | |

| Multi–G Clips (25g-50g-75g) | Activates at three different levels |

|

A Complete ShockWatch Clip Impact Indicator Program

Success of the ShockWatch Program is measured by a reduction in damage. Preventing mishandling is the key to damage reduction.

In order to prevent mishandling, communication with everyone in the supply chain is key.

Contact us for further information on the ShockWatch Program or if you would like any information on ShockWatch Clips Activation Curves.

Benefits

- Acts as a visual deterrent to improper handling

- Reduces mishandling through awareness

- Provides indisputable evidence of mishandling

- Alerts recipient to inspect contents before acceptance

- Promotes chain of accountability for all product handling

- Confirms effectiveness of packaging

- Helps identify trouble spots in supply chain, from production to transportation and storage

- Helps increase quality of product from dock to dock