ShockWatch’s quality impact indicators are an easy way to provide quality assurance of products and deter mishandling which can result in damaged goods. ShockWatch has some clients who have, prior to investing in their products, experienced up to 60% product damage during shipment. After employing a ShockWatch Impact Indicator and an implementation program, this figure was reduced to under 10% in some instances.

A Shockwatch partner in the US, SpotSee, was involved in a case study with a garage door manufacture who was experiencing significant losses derived from damaged goods being received by customers. They did not know if the damage was occurring before it left their facility or after shipment to the customer. Because the doors were so large and heavy, processing returns from customers was a very costly exercise. The goal was to eliminate the returns for which they could be liable.

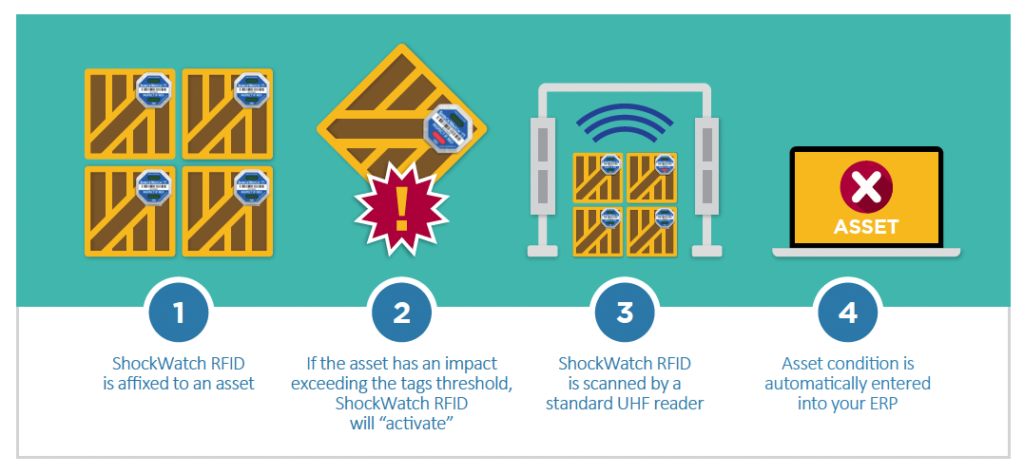

To ascertain if there was any damage occurring within the facility, the SpotSee RFID impact indicator was implemented to identify if the garage doors were being mishandled in manufacturing or when moving between areas within the company’s facilities e.g. from manufacturing to distribution. There were several key transition points where garage doors would physically change hands. The company placed a standard UHF RFID reader over the entrance and exit door of each transition point to read the status of the RFID indicator. The RFID’s were scanned at these key transition points by a standard UHF reader and the asset condition was automatically entered into the client’s ERP database.

The company found that the majority of their product damage occurred after leaving the manufacturing facility but before it arrived at the distribution warehouse. The company used this information to improve it’s packaging and was able to reduce their internal supply chain damage by 40%. Ultimately, annual claims were reduced by 60%.

A noticeable shift in behaviour by workers and instances of unacceptable handling were reduced and accountability by workers increased.

This case study is a powerful indicator that points to the success of SpotSee’s RFID Impact Indicators.

RFID technology is an effective way to improve inventory control and mitigate asset liability. Improving supply chain processes is a common goal within the logistics sector. With UHF readers allowing for automatic registration of asset condition, visual inspections may become redundant thus saving operations teams valuable time.

ShockWatch supplies SpotSee RFID Impact Indicators Australia wide. Give us a call today on 1300 074 625 to have any questions about quality assurance of products answered. ShockWatch is open for business Monday to Friday, 8:00am-5:00pm.