MAG 2000 impact indicators

are cost-effective, resettable and reusable devices designed to monitor the handling of fragile goods and freight containers greater than 227 kgs.

The device is also widely used on rail cars and trucking fleets to monitor for excessive impacts during humping or latching as well as transformers or rotors for example.

How the MAG 2000 works

The MAG 2000 impact indicators utilise two magnets, the bottom magnet held rigidly in place and an upper magnet held in place by the mutual magnetic field attraction. Each MAG 2000 is factory set to a particular g force. When acceleration due to impact or vibration is strong enough to create a force greater than the magnetic force of the particular MAG 2000, the upper magnet is forced off its “home” position and appears in a visible position within the device.

The MAG 2000 also indicates the angle of impact by the position of the indicator magnet. The g-activation level is factory set and available in a wide variety of settings from 2G to 20G. Selecting the most appropriate MAG 2000 can be done using our MAG 2000 Selection Guide.

Resettable and tamperproof

A uniquely designed key is supplied to unlock the cover on the unit. This key allows the product to be reset after activation and resists tampering.

Economical solution to reduce your damage related costs

MAG 2000 impact indicators offer an economical solution to prevent damage during product transit. The MAG 2000 can be reset and reused and is tamperproof.

Indicate when mishandling has occurred with MAG 2000 impact indicators

While MAG 2000 impact indicators can be mounted on either a product or the product packaging. However, it is generally advisable that the MAG 2000 impact indicators be placed on the product since the impact experienced by the product itself is generally more important than the impact received by the packaging.

The placement of the MAG 2000 impact indicators will affect the selection of the proper sensitivity.

Applications

- Auto and Truck Parts

- Electronics – Computer Hardware

- Textiles

- Glass

- Consumer Products

- Construction – Supplies and Fixtures

- Energy and Utilities

- Metal Fabrication

- Railroads

- Consumer Electronics

- Equipment Rental

- Auto and Truck Manufacturers

- Scientific and Technical Instruments

- Aerospace and Defense

- Industrial Equipment

- Medical Devices and Supplies

- Logistics / Transport and Storage

- Electronics – Telecommunications

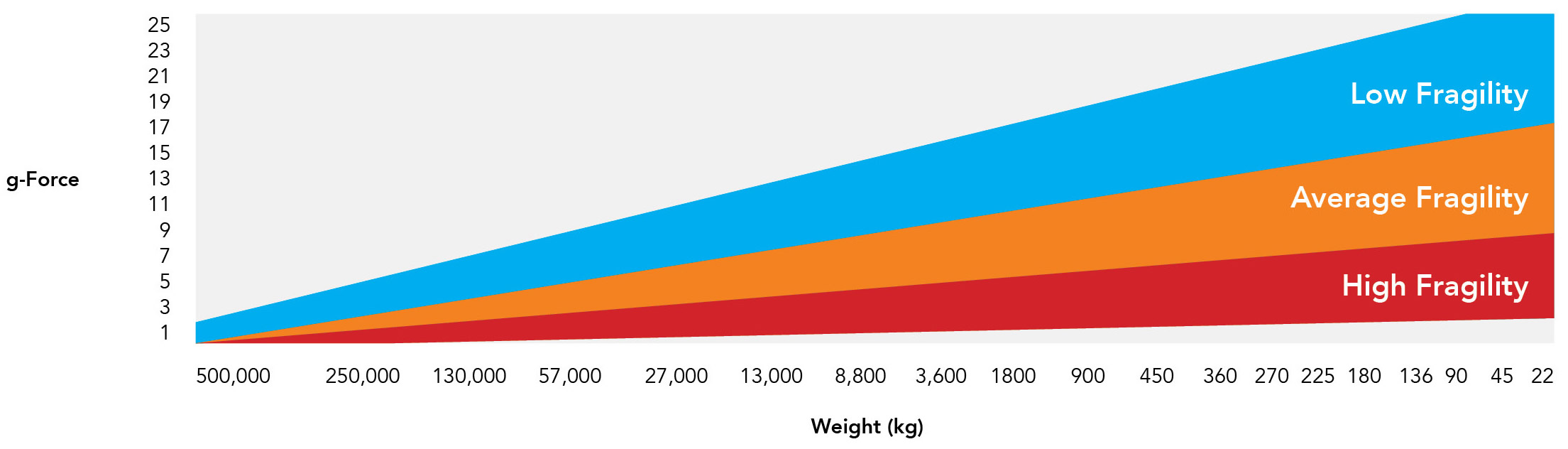

MAG 2000 Selection Guide

There are two things you need to know to begin selecting a MAG 2000 sensitivity: shipment weight (kgs) and fragility (Low, Average, or High).

The selection guide should always be used as a starting point only. The MAG 2000 that will be best suited to your application will also take into account product packaging.

Low Fragility Zone — Applicable in situations in which both visible and hidden damage is possible, and a single extreme impact will cause damage to product. Pertains to products transported via a variety of modes.

Average Fragility Zone — Applicable in situations in which there is a moderate degree of stability and survivability built into the product, and in which a standard mode of transportation is used.

High Fragility Zone — Applicable in situations in which hidden damage is the key concern. Typically, these products will be constructed of low tolerance components such as data storage drives, optical lenses, or any other products that require precise alignment. Pertains to most products that require specialized modes of transportation, such as air-ride vans or extended travel in hydro-cushion railcars.

Contact us for further information on MAG 2000 Activation Curves.

Benefits

- Acts as a visual deterrent to improper handling

- Reduces mishandling through awareness

- Provides indisputable evidence of mishandling

- Alerts recipient to inspect contents before acceptance

- Monitor for excessive impacts during humping or latching on rail cars or trucking fleets

- Promotes chain of accountability for all product handling

- Confirms effectiveness of packaging

- Helps identify trouble spots in supply chain, from production to transportation and storage

- Helps increase quality of product from dock to dock